Automation’s Impact: A 5-Year Outlook on US Manufacturing Jobs

The Impact of Automation on Manufacturing Jobs in the US: A 5-Year Outlook suggests a complex transformation, with routine tasks being automated, leading to potential job displacement but also creating new opportunities requiring advanced skills in technology and data analysis.

The manufacturing sector in the United States is undergoing a significant transformation, largely driven by increasing adoption of automation technologies. This article delves into the impact of automation on manufacturing jobs in the US: A 5-Year Outlook, exploring both the challenges and opportunities that lie ahead for American workers.

The Rise of Automation in US Manufacturing

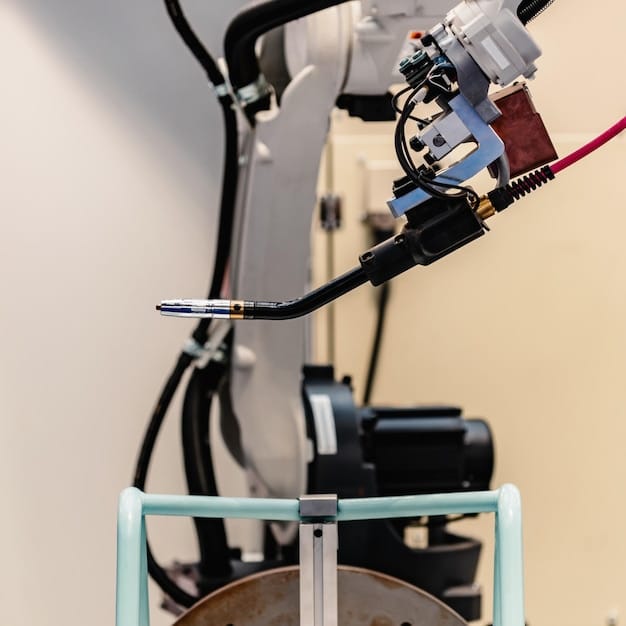

Automation is no longer a futuristic concept; it’s a present-day reality in US manufacturing. From automated assembly lines to sophisticated AI-powered quality control systems, manufacturing plants across the country are integrating these technologies to boost productivity and efficiency.

Key Drivers of Automation

Several factors are propelling the rapid adoption of automation technologies in the manufacturing sector.

- Increasing Global Competition: US manufacturers face intense competition from overseas, making automation a necessity to maintain cost-competitiveness.

- Labor Shortages: A shortage of skilled labor in manufacturing is further accelerating the adoption of automation.

- Technological Advancements: Rapid advancements in robotics, AI, and machine learning are making automation technologies more accessible and cost-effective.

The Current State of Automation

The application of automation varies across different manufacturing industries. Some sectors, like automotive and electronics, have already embraced automation extensively, while others, such as food processing and textiles, are adapting at a slower pace. However, the overall trend is unmistakable: automation is becoming increasingly prevalent across the board.

In conclusion, the rise of automation in US manufacturing is being driven by global competition, labor shortages, and rapid technological advancements, and its effect varies across industries.

Job Displacement: Realities and Concerns

One of the primary concerns surrounding automation is its potential to displace workers in the manufacturing sector. As machines become more capable of performing tasks previously done by humans, the need for manual labor decreases.

Jobs at Risk

Certain types of manufacturing jobs are more vulnerable to automation than others. Repetitive, manual tasks that require little skill or decision-making are prime candidates for automation.

- Assembly Line Workers: Tasks involving repetitive assembly of components are easily automated using robotic arms and automated machinery.

- Machine Operators: Traditional machine operators are being replaced by automated machines programmed to execute precise tasks with minimal human intervention.

- Quality Control Inspectors: AI-powered vision systems can now detect defects with greater accuracy and speed than human inspectors.

The Impact on Workers

Job displacement due to automation can have significant consequences for workers, including loss of income, reduced job security, and increased competition for remaining manufacturing positions.

To summarize, job displacement, especially for assembly line workers, machine operators, and quality control inspectors, is a major concern due to automation.

The Creation of New Manufacturing Roles

While automation poses a threat to some manufacturing jobs, it also creates new opportunities for those with the skills to operate, maintain, and improve automated systems.

Emerging Job Categories

The rapid adoption of automation is leading to the emergence of various new job categories within the manufacturing sector.

- Robotics Technicians: These technicians are responsible for installing, maintaining, and repairing robots and automated equipment.

- Automation Engineers: Automation engineers design, develop, and implement automated systems to improve manufacturing processes.

- Data Analysts: With increasing amounts of data being generated by automated systems, data analysts are needed to extract insights and optimize performance.

The Skills Gap

The creation of these new jobs highlights the need for workers to acquire the necessary skills to succeed in an increasingly automated manufacturing environment. Addressing the skills gap is crucial to ensuring that US workers can benefit from the opportunities created by automation.

In conclusion, automation is creating new jobs for robotics technicians, automation engineers, and data analysts, but closing the skills gap is critical for US workers.

Education and Retraining Initiatives

To help workers adapt to the changing landscape of manufacturing, education and retraining programs are essential. These initiatives can equip workers with the skills they need to transition into emerging job categories.

Government Programs

The government plays a vital role in supporting education and retraining through various programs. These programs can provide funding for training, apprenticeships, and other initiatives designed to help workers acquire new skills.

Here’s an overview of available resources:

- Workforce Innovation and Opportunity Act (WIOA): WIOA provides funding for state and local workforce development programs that offer training, job search assistance, and other services.

- Trade Adjustment Assistance (TAA): TAA provides assistance to workers who have lost their jobs due to foreign trade, including training, job search assistance, and income support.

Private Sector Investments

Many companies are also investing in education and training programs for their employees. These programs range from on-the-job training to partnerships with community colleges and vocational schools.

To conclude, government programs such as WIOA and TAA, along with investments from private sector, are crucial to education and retraining for workers in manufacturing sector.

The Broader Economic Impact

The impact of automation on manufacturing jobs extends beyond individual workers and companies. Automation can have significant ripple effects on the broader economy.

Increased Productivity

One of the primary benefits of automation is increased productivity. Automated systems can operate 24/7 with minimal downtime, leading to higher output and reduced costs.

Economic Growth

Increased productivity can drive economic growth by making US manufacturers more competitive in the global market. This can lead to increased exports, higher revenues, and job creation in other sectors of the economy.

Potential Challenges

However, the economic benefits of automation may not be evenly distributed. Job displacement can lead to increased income inequality and social unrest if not addressed effectively.

Automation’s broader economic impact results in increased productivity and growth, but income inequality may arise, underscoring the necessity of equity.

A 5-Year Outlook: Key Trends and Predictions

Looking ahead to the next five years, several key trends and predictions can inform our understanding of the impact of automation on manufacturing jobs in the US.

Continued Adoption

The adoption of automation technologies is expected to continue accelerating in the coming years. Advancements in AI, machine learning, and robotics will make automation more accessible and cost-effective, driving its integration into even more manufacturing processes.

Shifting Skill Requirements

As automation becomes more widespread, the demand for workers with advanced technical skills will continue to grow. Workers will need to be proficient in areas such as data analysis, robotics programming, and automation systems maintenance.

Government and Industry Collaboration

Addressing the challenges and opportunities presented by automation will require close collaboration between government, industry, and educational institutions. Government policies can support education and training, while industry can provide insights into the skills needed in the future workforce.

In summary, over the next five years, automation adoption will continue accelerating, shifting skill requirements and necessitating collaboration between government, industry and educational institutions.

| Key Point | Brief Description |

|---|---|

| 🤖 Automation Surge | Increased automation in manufacturing driven by technology & competition. |

| 💼 Job Transition | Some jobs will be displaced, but new, skilled positions will emerge. |

| 📚 Skills Imperative | Education and retraining are essential for workers to adapt. |

| 📈 Productivity Gains | Automation boosts output and global competitiveness. |

Frequently Asked Questions

▼

Automation may lead to a decrease in certain manufacturing jobs, particularly those involving repetitive tasks. However, it can also create new jobs in areas like robotics and data analysis.

▼

Critical skills will include programming, robotics, data analysis, and problem-solving. Adaptability and continuous learning will be essential for workers to stay relevant.

▼

Programs like WIOA and TAA offer training and support for workers displaced by automation or trade, helping them acquire new skills and find new employment opportunities.

▼

Companies should invest in training programs for their employees, foster a culture of innovation, and carefully evaluate the potential impact of automation on their workforce.

▼

Automation can lead to increased productivity, higher quality products, reduced costs, and improved competitiveness in the global market, ultimately boosting the US economy.

Conclusion

The impact of automation on manufacturing jobs in the US: A 5-Year Outlook presents both challenges and opportunities for American workers. By fostering education, investing in retraining initiatives, and promoting collaboration between government, industry and educational institutions, the United States can navigate the transformation that automation brings, ensuring a future where workers and technology thrive.